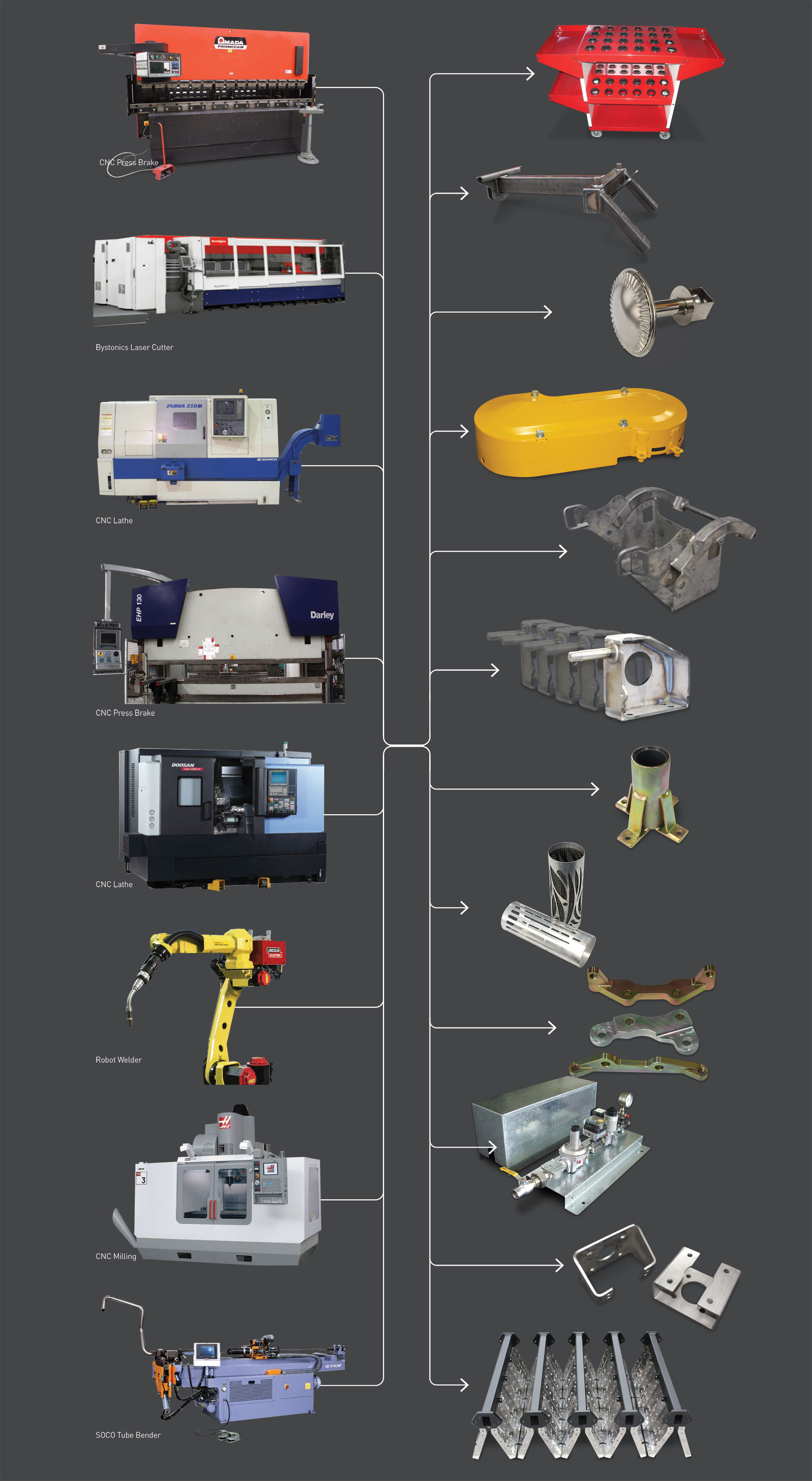

Computer controlled fabrication

Making complex metal components requires integration of many discrete processes, such as laser cutting, sheet folding, tube bending, robot welding, drilling, milling and turning.

Our state of the art computing systems and fabrication equipment enables each stage to be managed with the highest possible degree of precision and consistency.

We use a combination of CAD and ITMS software to optimise process design, manage stock flows and ensure quality control.

The diagram below illustrate how these multi-faceted, computer integrated fabrication capabilities enable us to deliver all sorts of complex metal components to meet the highest standards of quality.