Magic Mobility

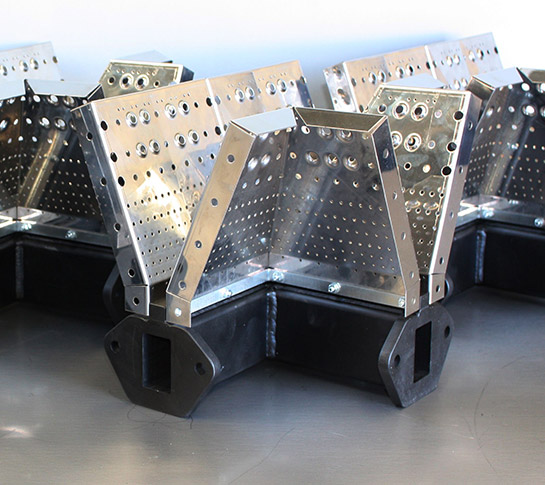

Magic Mobility makes hi-end, all-terrain powered wheelchairs that are marketed in more than 10 countries worldwide.

Our powered wheelchairs are made to last. They’re designed tough to enable their users to go wherever they want and get the most of life.

We’ve been working with Bruce Towns Engineering for more than twenty years, since we started out. Their attention to detail and willingness to make the smallest adjustments, and suggest improvements is invaluable.

We almost never have to return a part. Although it can cost more per item, we’re paying more up front to never have any problems down the track. It’s far more cost effective in the long run to avoid any rework or having to return parts overseas for correction.

From a new product point of view, the team at Bruce Towns are very willing to take a collaborative approach to get the best results for everybody. They work with you to get the quality built into the design. They want a full partnership.

We certainly wouldn’t be where we are now without them.

Penske Power Systems

Penske Power Systems supports customised applications of high quality diesel engines to power a range of industrial systems such as mining extractors, emergency generators, and so on. They come to Bruce Towns Engineering for complex new parts they need to install, maintain and repair these power systems, which are often required to run continuously for years.

Bruce Towns Engineering provides fantastic, high-quality workmanship. When we require an innovative solution, particularly any critical work, we go straight to the team at Bruce Towns. We trust the team to ask us about anything that is unclear or ambiguous, to make sure the job is done right. The team at Bruce Towns are always candid about timing and what we can expect. If there is any doubt, they under-promise and over-deliver – never the other way around.

For example, we’ve been using Bruce Towns Engineering for more than ten years to supply critical moving parts to refurbish our mining excavators. We have over 40 refurbished excavators, working constantly, feeding mine conveyers and trucks. If an excavator stops working, the mine stops working. Critical excavator components made by Bruce Towns Engineering have now been running for at least a million hours since we installed them, and they have never broken down or had any problems. That’s why it makes sense to rely on the team at Bruce Towns when it counts.

Techrite Controls Australia

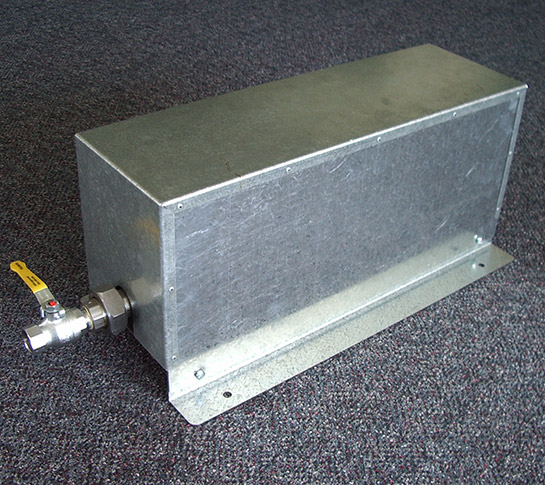

Techrite Controls Australia designs and supplies gas safety and combustion equipment for a wide range of industries such as steel, nickel and aluminium smelting, power generation, plaster board, textiles and food manufacturing, oil drilling and mining. They also supply componentry such as gas valving, ignition controls, pressure switches, thermostats, spare parts and so on to local OEMs of heating and commercial catering equipment.

Techrite originally sourced parts from a number of small businesses, mainly using manual operations. With our robotic and CNC machinery we were able to offer them much greater consistency and precision across a wide range of parts, and so provide better quality components from a reduce supplier list.

We are now one of Techrite’s main Australian suppliers of manufactured parts, from complete burner and valve assemblies through to brackets, enclosures and other machined parts.

Bruce Towns Engineering has been a major supplier to Techrite Controls Australia for over 15 years. During that time their staff has always been very helpful and innovative. Bruce Towns Engineering is a supplier that we can always rely on to deliver high quality product in the time frame specified.

I highly recommend them as a supplier and am sure they will continue to grow and prosper in future years

Ego Pharmaceuticals

Ego Pharmaceuticals manufactures a wide range of high quality cosmetics and pharmaceuticals. To keep their state of the art production facility running at full capacity they often require custom designed metal components to set up new production lines, enable changes to packaging design or to replace worn or damaged parts.

Ego Pharmaceuticals rely on Bruce Towns engineering to deliver the bespoke and sometimes complex parts they need in a timely and cost effective way. For more challenging projects, they may work with Bruce Towns Engineering to figure out the best way to solve a difficult fabrication design problem.

We have been using Bruce Towns Engineering for years. They offer high quality at a competitive price, and they deliver when they say they will. They have also helped us out of a few tough situations when we have required very fast turnaround times. Thank you to everyone at Bruce Towns for your exceptional service!

A&A Di Medio

A&A Di Medio are a leading supplier of concrete agitators for large fleets across Australia. Many of the complex components required to turn and tip the agitators require high-precision engineering.

A & A Di Medio & Son has been working with Bruce Towns Engineering for over 30 years. They’re a very professionally organised company, and very precise in terms of delivery. We’ve never had any issues regarding quality, and I know that if we ever did they would resolve it straight away.

When we first began working with them on our agitators they came up with a lot of engineering solutions. Since then they have always been proactive with suggestions about better solutions made possible by new technology, such as laser cutting. We have no hesitation in recommending them to any other manufacturer looking for top quality precision and long-term partnership from an engineering supplier.